Industry solution

One of the typical WinTool solutions for the Systems industry

World Record in Setting Up Tools for a Job!

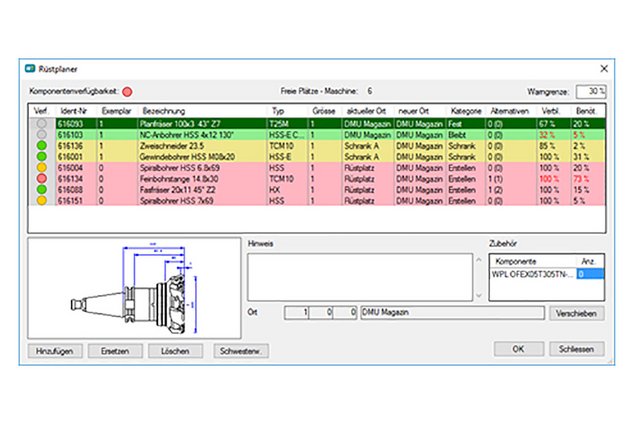

Exclusively, WinTool presents a world premier: the WinTool Setup Planner. With the Setup Planner, you are able to immediately locate any tool in your shop, whether it’s in the crib, on machine magazines, in storage racks, assembled or disassembled. The Setup Planner calculates the net list comparison for a job, finds all available rack tools that are ready or can easily be reconfigured, and checks stock availability and remaining tool life. Machines are setup with minimal effort and yield maximum production runtime!

The Task

- Your production should tick like a Swiss watch! Machines should produce nonstop with minimal setup / down time

- Production workflow should be integrated, lean, standardized, and resilient

- ALL tools should be found, so you will use everything, you have!

Your Benefits

- Eliminate costly machine setup work and get more available machine capacity

- Find your tools and know if they are available or scheduled for other jobs

- Robust work procedure according to plan and requirements / stay flexible!