Collect cutting data from the machine directly into WinTool

Highest reliability with creating the cutting condition database in WinTool (for CAM programming) through loading it systematically directly from the machine. Changes regarding cutting conditions in the CAM programming and / or on the machine can be reproduced and back logged consistently and reliably. Optimization potentials are shown in costs savings over the cumulative cycle time as well as the machine hourly rate over all comparable processing.

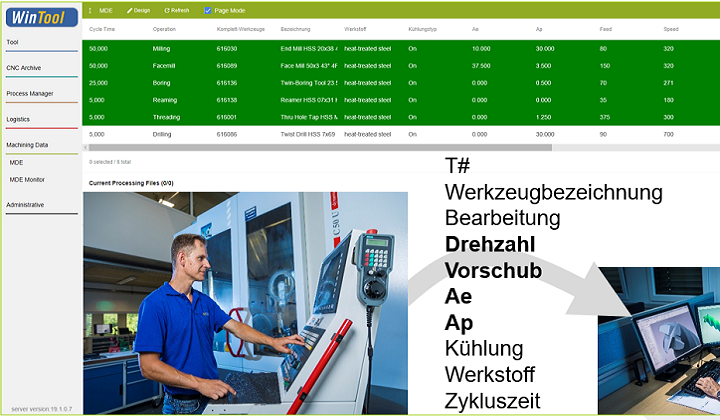

The new WinTool Cutting Data Collection Module allows you to save cutting data from the machine continuously and directly into WinTool to close the loop back to CAM programming! Constantly and systematically compare cutting data from the machine with the cutting expert module in WinTool , to continuously improve productivity through CAM programming! Every operation over all tools, machines, orders, or batch sizes are recorded and automatically analyzed for optimization in terms of cycle time and other processing data (e.g. Ae, Ap, F, S).

► Convince yourself; ask for a demo!